C Frame Pipe Straightening Hydraulic Press 315Ton

Basic Info

Model No.: Yz41

Product Description

C Frame Powder Forming Hydraulic Press Machine

Single-arm hydraulic press Scope: This series of single-column correction press-fit hydraulic press is a multi-functional small and medium-sized hydraulic press, suitable for shaft parts, profile correction and press-fit of bushing parts. At the same time, it can also complete the bending, embossing, sleeve shape, stretching of simple parts and other process actions, and can also be used to suppress powder and plastic products that are not very strict. This series of products are suitable for use in machine tools, internal combustion engines, textile machinery, shafts, bearings, washing machines, automotive motors, air conditioner motors, electrical appliances, military enterprises, and assembly lines of foreign-funded enterprises.

The single-column hydraulic press has independent power mechanism and electrical system. It adopts centralized control of buttons, which can realize the working pressure and pressing speed of the three working modes of adjustment, manual and semi-automatic. The stroke and range of no-load fast-down and deceleration can be based on The process needs to be adjusted, and the ejector process can be completed with three processes: ejector process and stretch process. Each process is selected for constant pressure and fixed process. The constant pressure molding process has Ejection delay and automatic return trip.

Single-column hydraulic press, C frame hydraulic press, the fuselage is C-type single-arm structure, submerged arc welding, vibration treatment after welding to ensure the degree of deformation of the fuselage. The hydraulic system is located inside the fuselage, which is beautiful in appearance and easy to operate. It is mainly used in the process of stretching, forming and pressing metal products. It can also process non-metallic materials, pressing of powder metallurgy products, correction of shaft parts, press-fit of sleeve parts, and shaping and trimming of metal products. This series of presses is equipped with independent hydraulic and electrical control system. It adopts centralized control of buttons, which can realize two kinds of forming processes: fixed pressure and constant pressure. It has functions of pressure display, stroke and pressure adjustment. And the series has four-column guide column guide to improve product accuracy, and the column and piston rod are quenched after copper plating and hard chrome to ensure the surface wear resistance and high roughness. The oil pump inlet is equipped with unique filtration. The device ensures the service life of the oil pump and valve. The oil connection is made of imported high-pressure hose, which greatly reduces the noise of the machine. In addition, according to user requirements, additional components such as imported PLC, grating protection and human-machine interface (touch screen) can be configured. For the special requirements of customers, we can design and produce specially to meet the requirements of customers' production process.

The working medium used in the single-column hydraulic press not only transmits the pressure but also ensures that the working parts of the machine work sensitively, reliably, with long life and less leakage.

Feature

1. It has the characteristics of good structural rigidity, good guiding performance and fast speed.

2. Convenient manual adjustment mechanism can adjust the pressure head or the upper table to press at any position in the stroke, and can also adjust the length of the fast forward and the working process arbitrarily within the design stroke;

3.l The solid welded open structure allows the fuselage to be rigid enough to have the most convenient operating space.

Parameter

| Item | Unit | Yz41-10T | Yz41-25T | Yz41-63T | Yz41-160T | Yz41-200T | Yz41-250T | |

| Nominal Force | KN | 100 | 250 | 630 | 1600 | 2000 | 2500 | |

| Slide Stroke | mm | 120 | 160 | 250 | 350 | 400 | 500 | |

| Max.Liquid Force | Mpa | 5.5 | 5.5 | 6.28 | 13 | 22.6 | 25 | |

| Workbench | L-R | mm | 200 | 200 | 200 | 250 | 300 | 500 |

| F-B | mm | 300 | 300 | 300 | 350 | 400 | 700 | |

| Overall Dimension | L-R | mm | 500 | 500 | 500 | 650 | 900 | 1400 |

| F-B | mm | 400 | 400 | 400 | 550 | 600 | 1000 | |

| H | mm | 1450 | 1450 | 1600 | 1900 | 2500 | 3200 | |

Components

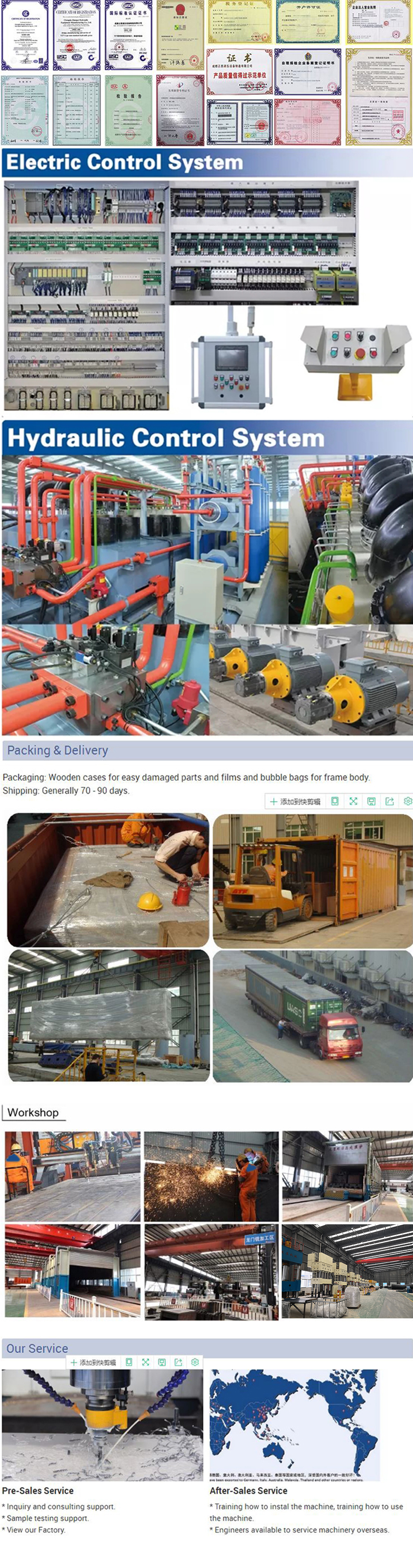

Certificate

After-sale

1.Personnel training

Free training for about one week.

2. After-sale service

One year warranty.During warranty period,free maintenance service can be provided.(except man-made faults or damages arising from irresistible natural factors)

3.Installation

Customers need to pay the commission to our proffessional engineer, and travel expense is on foreign customer.(Including round ticket and accommodation cost)

Our company is an ISO 9001 certified Company, and as an approved supplier for the automotive sector, has also received the CE certificates.This demonstrates that the Quality Assurance System has been fully introduced and adopted, in the interests of providing absolute reliability in our products and careful attention to our customers.

FAQ

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .

You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What's your main products of your company?

A: We specialized in all kinds of machines ,such as 1-16000Tons Hydraulic Press,SMC/BMC/GMT/DMC/LFT/GRP/FRP Press,Hydraulic Deep Drawing Press,Hydraulic Forging Press,Metalworking/Stamping Press.

3: Where is our factory located? How can I visit there?

A : Our factory is located in Chengdu City ,Sichuan Province,China. You are warmly welcomed to visit us.

4: What's the MOQ?

A: 1 set .(Only some low cost machines will be more than 1 set )

5: How about your delivery time?

A: Generally 90 days. The specific delivery time depends on the items and the quantity of your order. Sometimes we have some in stock.

6: Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

7: How do you make our business long-term and good relationship?

A: 1.We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

Product Categories : C Type Hydraulic Press > Pipe Straightening Machine