Automatic Compact Feeding line

Basic Info

Model No.: MAC4-1300H

Product Description

| Product Description |

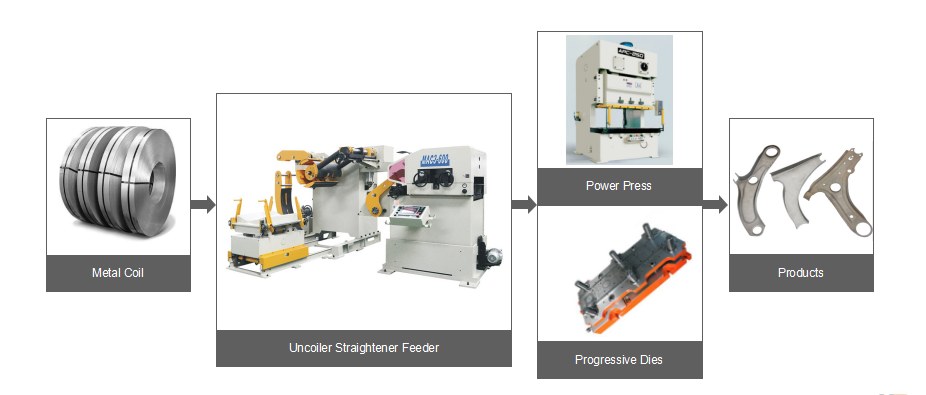

The particularly Automatic Compact Feeding line is made up of two main units: the feeder-straightener unit and the uncoiler unit. Both machines rest on an welded connecting base.

The feeder-straightener unit is directly connected to the press by means of output bracket which allow the sheet metal to be vertically aligned to the press machine and progressive die, at the same time as maintaining its horizontal rigidity. The uncoiler is made up of a welded steel structure which supports the four spoked, hydraulic expanding mandrel. The mandrel is driven by a hydraulic motor which is coupled to a pneumatic Disc Brake. The uncoiler can be equipped with a hydraulic roll with hydraulic motorised wheel and the feeder-straightener can be fitted with automatic hydraulic shearing machine and oiling machine.

Automatic Compact Feeding line Model:MAC4- Specifications Model MAC4-1000H MAC4-1300H Material Width(mm) 70-1000 70-1300 Material Thickness(mm) 0.6-6.0 Max.Coil Weight(kg) 7000 10000 Max.Coil O.D.(mm) 1400 Coil l.D.(mm) 508 Feed Length(mm) ~500* Max.Line Speed(m/min) 16-24 StraightenerRoll (pcs) upper6/lower5 Feed Roll(pcs) 2 Main Motor AC15 AC22 Mandrel Expansion Hydraulic Reel Motor(kw) 3.7 7.5 Power(V) 3phase 220V/380V/50HZ Operating Air(Mpa) 0.49

Remarks:

1)The above figures are the material having yield strength σs=600N/mm².

2)Specifications are subject to change for improvement without notice.

Products Show

The Main Detailed Parts of Automatic Compact Feeding line as below:

1. Coil Car---Hydraulic power, wear-resisting surface2. Decoiler Mandrel ---Hydraulic Expansion, Delta Inverter

3. Pressing Arm---Coil well-knit, no disperse

4. Limiting Arm--- Locating coil, avoid coil shuffling

5. Support Arm---Auxiliary support coil

6. Coil Inlet---With supporting swing arm

7. Control Cabinet---Weinview Touchscreen

8. Straightening Part---GCr15 steel straightener rolls

9. Handwheel --- Straightening value adjustment

10. Shearing Unit---Hydraulic shear (Optional)

11. Lubrication Unit---Automatic control, 20L (Optional)

12. Outlet Bracket --- Adjustable length

| Application |

Automobile stamping, appliances manufacturing, computer and electronic componets, hardware and metal parts etc industry.

Automotive Parts: Bracket, Damper, Barke Pad, Tie Bar, Electric Accessory, Shell Parts Of Printers, Computer Frame,Slide Rail of Car Seat, Splash Shield of car body and etc

MAC4 Automatic Compact Feeding line is working in our customer's factory.

Automatic Compact Feeding line for making the bracket coil sheet feed line.

This machine is workinng in one of our customer's factory, they produce U type parts with Compact Decoiler And Feeder Straighteners Press Feed Systems.

With the Yaskawa Servo Systems and Mitsubishi PLC control, the feeding line can reach ±0.15mm feeding accuray.

| Our Company |

Mayflay company are a high quality manufacturer of all types of Coil Handling Equipment and Press feeding equipment in China. Manufacturers of separate Decoilers, Straighteners and Servo feeders, and can provide an excellent range of combo 2 in 1 decoilers and Straighteners, and also the very popular Compact Press Feed lines which will reduce floor space and dramatically improve threading time on heavy duty coils.

Mayflay company has been learning Japanese technology and using high standards of principle in the parts selection, assembly process and spare parts, focus on designing and providing providing innovative, cost-effective Coil Processing Solutions and Automatic Stamping Line solutions. Mayflay develops with cutting-edge technology and considerate service. Mayflay offers one stop solution to solve the problem of feeding coil strips into the press so well, and increase production so substantially. Today, Mayflay is a dedicated enterprise featuring facility manufacturing with good reputation, professional skills, modern management, extensive sales network, and ingenious marketing.

Mayflay is not the best in the world, and the price is not the cheapest. But we can provide excellent products to reach your requirements and help you obtaining the greatest economic benefits.

| Packing & Delivery |

Packing Details : Wooden case

Delivery Details : 30-70 workdays

Shipping way: ocean shipping

| FAQ |

1. Would you provide OEM/ODM service ?

We are providing OEM services for our competitors from European country and Janpan company.

2.What certificates have you got?

Our company is verified by ISO9001.We got the certifications of CE for the products.

including Feeder machine ,uncoiler machine , decoiler machine, high speed press machine and etc.

3.What is the delivery time for our machine?

Feeder , uncoiler machine are 1-20 workdays.

High speed press machine are 5-35 workdays.

Decoiler straightener feeder 3 in 1 machine are 15-65workdays.

Uncoiler straightener 2 in 1 machine are 1-25 workdays.

Sometime ,our machine are with stock.

4.What is the quality control in the company?

We inspect the machine according to ISO 9001 standard and test the machine before.

delivery and we make our machine with CNC equipment in our factory. Our machines are high quality ones.

Product Categories : Decoiler Straightener Feeder > High Strength Steel Coil Feed Lines